Website on alibaba: whfn.en.alibaba.com

AdvancedEquipments Equipments Spare Parts Additives

Air-Lock valve

Air-Lock valve

Air-lock valve is specially designed as power and buik material discharge device under silo, storage bin, hopper etc.It is different from other feeders as it has the features that it can control the material discharge from siol, mixer, cyclone or hopper uniformly,and it can lock the air with material's gravity.

Get more Dust collector

Dust collector

Dust gas enters the middle and lower enclosures through the air inlet of the precipitator. The dust and gas are separated through the filter of the filter bag. Dust is adsorbed on the surface of the filter bag, and clean air is discharged from the air outlet through the filter bag. Increasing the amount of dust deposited on the surface of the filter bag over time is increasing. According to the procedure set by the pulse blower, the pulse blow valve triggers on in sequence.Compressed air inside the air bag is instantly blown out from each hole of the injection pipe and sprayed into the corresponding filter bag via the venturi. The dust adsorbed on the surface of the filter bag then falls off into the hopper and is discharged through the discharge valve Directly into the warehouse.

Get more Sewing machine

Sewing machine

The sewing machine is a device for sewing product packaging bags. It is easy to carry, easy to operate, and easy to maintain. It is used to seal various packaging bags.

Get more Heat exchanger

Heat exchanger

Plate heat exchanger is a new type of high efficiency heat exchanger which is made of a series of corrugated metal sheets. A thin rectangular channel is formed between the plates, through which the heat exchange between liquid, liquid and vapor can be achieved.

Get more Crystallizer

Crystallizer

This crystallizer can be made from SS304, SS316L, Ti, Hastelloy-C, PTFE lined or other materials, mainly used for refined naphthalene, borneol, Lithium Hexafluorophosphate, pharmaceutical, etc, and also crystallization of other products. Jacket structure is applied in this equipment that makes big cooling area available. Ribbon agitator is installed in the barrel with fast cooling speed of materials and efficient crystallization. Meanwhile, through the ribbon agitator, all the materials in the barrel can be cooled uniformly, and ensure that grains after crystallizing will have uniform size.

Get more Static mixer

Static mixer

The static mixer is a non-power efficient mixing equipment with very wide range of availability. With only few energy of the fluid to be converted to a mixed energy and by means of the precisel designed blades, the fluid will enter into the mixer tube, and result in the functions of split, reversed, mixed and rectifier so to achieve a perfect dispersion and mixture purpose. Compared with the traditional mixer, Static Mixer is with compact structure, low energy consumption, less investment, flexible operation and no maintenance requirement. We can supply with SS304 or SS316L material, and PVC static mixer

Get more Air compressor

Air compressor

Imported top-grade main machine, as the third generation product of state-of –the art brand the world, with asymmetrical 5:6 tooth rotor, is provided with outstanding performance and high efficiency far beyond other similar-type brand. Full-intellectual control system and LCD screen, with self-diagnosis and protection devices, remote control and multi-host interlocking control, realizing unattended and high-tech operation. Y series three-phase asynchronous motor special for compressor, imported World famous brand bearing, F-level insulation, IP54 especially suitable for long-term use, safe and reliable. Imported oil filter, oil gas separation filter element, ternary separation, ensure oil content less than 0.001ppm, the trunk adopts metal pipe, safe for long –term operation without leakage or deformation, the V type drive belt is imported from Germany, and has a service life more than10000hous.

Get more Refrigerating machine

Refrigerating machine

The product features excellent heat insulation, corrosion resistance, low water absorption, shock absorption, radiation resistance, sound insulation, aging resistance, non-toxic and tasteless property, stable and durable insulation performance.

Get more Screw conveyor

Screw conveyor

Slurry screw conveyor is a kind of screw conveyor, and the production is made according to the DIN15261-1986 standard, and the design complies with JB/T7679-2008 "spiral conveyor" professional standard. Slurry screw conveyor is widely used in Petroleum project, for handling the slurry from well drilling.

Get more Closed cooling tower

Closed cooling tower

Closed cooling tower are of compact design, with single unit capacities from 30 to 500 nominal tons. Casing made in special alloy coated steel or stainless steel, cooling coils made in stainless steel, wet deck fills made in PVC. All raw materials are of high industrial grade, with superior corrosion resistant features. GHM towers are of high efficiency, lower power and water consumption rate. As package type towers, the installation generally easy. The towers dimensions can be customized to suit project footprint limit. GHM towers are widely applied in different fields, to cool circulating water, oil or other process fluids for Furnaces, Compressors, Power Generators, Converters, Transformers, and other machines; also used to reject heat in HVAC or Refrigeration System.

Get more Jet cooker

Jet cooker

Starch continuous jet cooker is the key equipment for producing glucose from starch through enzyme. It is widely applied for starch liquefaction used for MSG, alcohol, beer, citric acid, glucose, and maltoextrin. This equipment features in compact volume, high efficiency and low energy consumption. For producing glucose through dual-enzyme processing method, liquefaction is even, DE value is high, filtering speed is fast, and color is light. Jet cooker is not only suitable for middle and high-temperature enzyme, but also suitable for direct processing method used on photato, corn, rice, etc. Most of current MSG and starch glucose producers are applying this equipment, because its liquefaction effect is excellent, speed is fast and working noise is low. Adjusting device for jet cooker can be connected with automatic controlling system based on process demands.

Get more Hydrogen compressor

Hydrogen compressor

The compressor adopts oil-free lubrication structure and can run continuously for a long time. Meet the process requirements,suitable for hydrogen. All oil-free lubrication compressors with various parameters and requirements can be customized according to customer requirements.

Get more Hot air stove

Hot air stove

The furnace uses the high temperature resistant method so that its life is much longer than the life of the pipe arrangement hot air furnace. The furnace uses the smoke and air longitudinal splashing heat radiation sheets and the negative pressure smoke elimination mode. There is no dust collected on the heat exchange position. There is no need to carry out the cleaning.The heat feature is stable. Various coal and wood can be used as the fuel.The furnace is equipped with the air leading device and the combustion is complete.All the technical and economic indexes of the furnace have reached the advanced level at home.

Get more Cyclone

Cyclone

Cyclone Collector are often employed as an Initial Stage Collector to lighten heavy dusts loads before being sent to a Primary Stage Fabric Collector. By removing coarse particles from the gas stream, and allowing later stage Fabric Collectors to solely remove finer particles, these collectors increase the efficiency and service life of Fabric Collectors (Baghouses) and their Filters. Thus protecting your larger and most costly investment from unnecessary wear and tear.

Get more Acid mist absorber

Acid mist absorber

The FRP Acid Mist Gas Absorption Scrubber Tower is mainly composed of Water tank, Circulating water, Packing layer, Spraying system, Demister etc.The FRP Acid Mist Gas Absorption Scrubber Tower is designed to capture dust particles, VOCs, chemical fumes, and other water / chemically soluble fumes and Vapors generated in industrial process.Desulphurization spray layer is based on the upper part of the tower, the absorption tower slurry circulating pump corresponding to each spray layer. The nozzle configuration of spray layer is simulated designed by professional software in order to ensure good contact with alkali and acid reverse gasreaction; and finally reach purification effects. Demister installs in the upper of desulphurization tower, a total of two levels.The net is used to separate the entrainment of flue gas cloud droplets, and droplet concentration in flue gas export from mist eliminator is less than 75 mg/Nm3 (dry basis).At the same time, the equipment also has spray washing device to the tiny dust particles adhesion and desulphurization of flue gas crystallization on the demister system resistance increases.

Get more Modular air conditioning rack

Modular air conditioning rack

Modular air conditioning units are combined of a variety of air treatment sections, capable for air treatment of 6000-140000 m3/hour, can be used for air cooling, heating, dehumidification, purification, silencers and other treatments, widely used in electronics, instruments, machinery, pharmacy, food and the clean air conditioning systems of industrial and civil buildings. They boast compact structure, flexible configurations, beautiful appearance, reliable running, energy saving, low noise, easy erection and maintenance, and so on.

Get more Pressure curved screen

Pressure curved screen

Pressure curve screen is the indispensable slurry separating equipment of starch producing, adopts multilevel backflush to sieve can efficiently improve extraction rate and quality of starch. Its major screen surface is imported, sieve shell and incoming parts are used in fine quality imported stainless steel material, it’s the replacement of imported pressure curved sieve.

Get more Oil press

Oil press

Our series of screw oil press machine is composed of such components as electric appliance control, hot pressing, adjustment, driving and vacuum oil filter. The squeezing bolt is made of alloy steel treated by carburization to improve its surface hardness and wear resistance; the squeezing bolt are grinded by surface grinder to ensure the accuracy of oil thread and improve oil yielding rate; the standard components for power distribution, vacuum and heating are domestic famous brands to optimize machine configuration; the surface of machine are treated by stainless steel and chromium plating technology in accordance with the standards of food hygiene.

Get more Vibrating screen

Vibrating screen

The vibrating screen is a high-precision fine powder screening machine with low noise and high efficiency. It takes 3-5 minutes to change the net quickly. It is fully enclosed and suitable for screening and filtering of particles, powder and mucilage. The vibrating screen is made up of an upright motor as an excitation source. The upper and lower ends of the motor are equipped with an eccentric weight to convert the rotary motion of the motor into a horizontal, vertical, and inclined three-dimensional motion, and then transmit this motion to the screen surface. . Adjusting the phase angles of the upper and lower ends can change the trajectory of the material on the screen surface.

Get more Nitrogen generator

Nitrogen generator

We offer a wide range of PSA oxygen/nitrogen gas generators to be installed onsite for all industrial oxygen/nitrogen applications. Our oxygen/nitrogen gas generators are based on the well-known PSA (Pressure Swing Adsorption) technology using two pressurized columns with molecular sieves providing your business with unlimited oxygen/nitrogen generation on demand.

Get more Gravity curved screen

Gravity curved screen

Gravity curved screen offers proven and reliable performance in liquid solid separation for municipal and industrial application,particularly for screening fibrous and non-greasy solids,there are no moving parts,motors,or complicated connections. The screen is economical and simple to operate.In wastewater treatment plants,the Static hydraulic screen unit is renowned as a fine screen for pretreatment or use as grit dewatering equipment .Industrial users,such as meat processors,food processors,textile mills and recyclers ,rely on it for product recovery and wastewater treatment Pulp and paper mills use it for fiber recovery and rejects handing.

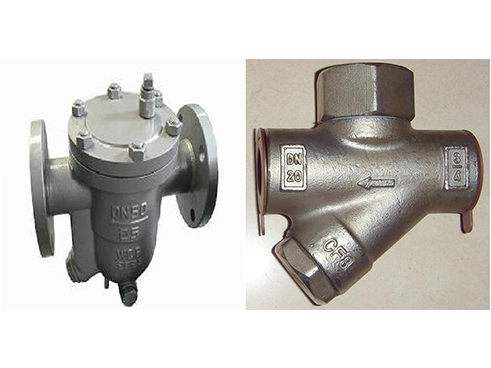

Get more Check filter

Check filter

DL series bag filter is mainly composed of filter cylinder barrel, filter cylinder cover and quick opening mechanism, stainless steel filter bag reinforced mesh and other main components. The liquid flows into the filter bag from the side inlet pipe of the filter housing. The filter bag itself is installed in the reinforcement mesh. The liquid can penetrate the filter bag of the required fineness level to obtain qualified filtrate, and the foreign particles are captured by the filter bag. TL series filter is composed of a number of filter elements mounted vertically on the filter plate in a closed cylinder. It relies on the filter element as the filter medium to perform pressure filtration in a closed container. The design structure is unique, the volume is small, the loading and unloading of the filter element is very convenient, and the cleaning of the filter cartridge is convenient and simple.

Get more Ion exchange column

Ion exchange column

Ion exchange technology is a purification technology that it removes impurities such as pigments, inorganic salts, and organic matter in materials. It is used widely in the purification of effective components such as starch sugar, sugar alcohol, citric acid, amino acids, antibiotics, and natural products.

Get more MVR evaporator

MVR evaporator

The MVR evaporator technology is that when the MVR evaporator runs, uses raw steam little or does not need to be added. In the MVR evaporator, the centrifugal fan compresses the secondary steam to a higher pressure, and the temperature of the secondary steam is increased accordingly. This means that the compressed secondary steam can be used as a heating source for the evaporator. At the same time, the condensate water can also be used to preheat the feed. Only a small area of the condenser is needed, and the amount of cooling water is also a little. It is a new type of high-efficiency and energy-saving evaporation equipment. It operates at low temperature and low pressure and reduces the input of cooling water system. It is used widely in starch sugar, sugar alcohol, citric acid, amino acid, fermented products, medicine, chemical industry and other industries.

Get more Multi-effect evaporator

Multi-effect evaporator

The multi-effect falling film evaporator and the forced circulation evaporator use the falling film evaporation principle to heat and boil .It vaporize part of the water to achieve the purpose of concentrating the solution. This unit adopts continuous production process. It has the advantages of large concentration ratio (1 / 5-1 / 10), wide viscosity range (<400CP), good heat transfer effect, large processing capacity, etc. It is suitable for evaporation about thermal sensitivity,high concentration, high viscosity and corrosive materials, it is used in the starch industry such the concentration of corn syrup and starch sugar, and the dairy industry such fruit juice , MSG ,milk,and the sugar alcohol industry such sugar juice , alcohol and lees filtration .

Get more Distillation tower

Distillation tower

The distillation tower adopts method of heating distillation to separate various substances which are different boiling points、densityand volatility from different equipments, thereby obtaining higher purity alcohol. It is used widely in fermentation, chemical industry, metallurgy, light industry, textile, alkali production, pharmaceutical, pesticide, electroplating, electronics and other fields.

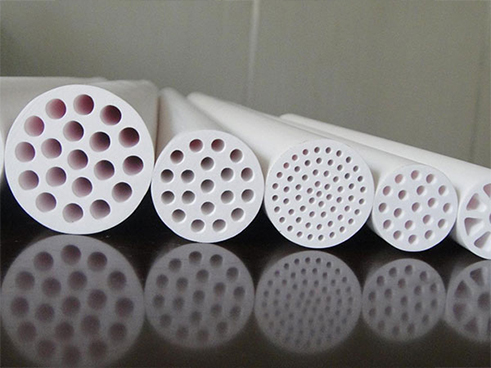

Get more MF membrane

MF membrane

Ceramic ultrafiltration membranes have high filtration accuracy, good strength, corrosion resistance, stable chemical properties, and high degree of equipment automation. They have been widely used in food fermentation, biomedicine, petrochemical, and environmental water treatment industries.

Get more RO membrane

RO membrane

RO (Reverse Osmosis) reverse osmosis technology is a membrane separation and filtration technology that uses osmotic pressure difference as power. It has been widely used in scientific research, medicine, food, beverage, seawater desalination and other fields.

Get more Belt press filter

Belt press filter

DYQ series belt filter press is a continuous pressure filter. It is used widely in papermaking, food, leather, chemical, building materials, coal industry and municipal sewage sludge dewatering, with strong adaptability and easy maintenance.

Get more Disc separator

Disc separator

The disc separator is a kind of decanter centrifuge which is used to separate the opacifying liquid with similar density.

Get more Solid-liquid separator

Solid-liquid separator

Screw extruder solid-liquid separator is used widely in agricultural production, starch production enterprises, food industry and paper industry.

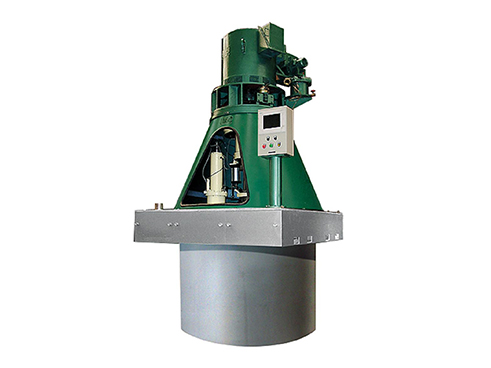

Get more Scraper centrifuge

Scraper centrifuge

The scraper discharge centrifuge is a filter centrifuge with fully automatic control, continuous operation and intermittent discharge. It can complete backflushing, feeding, deliquoring, washing, draining and discharging at full speed or variable speed. It is suitable for separating crystalline or short fibrous materials with a particle size (particle size) of 5 μm to 5 mm and a suspension concentration (solid phase volume ratio) of 1% to 40%. It is particularly suitable for large-load production and occasions requiring full washing.

Get more Centrifugal sieve

Centrifugal sieve

Centrifugal sieve is to separate the fine fiber (potato residue) and starch in the potato emulsion after filing and removing sand as much as possible. The equipment is used widely in large and medium-sized starch production enterprises, and can be used for the extraction of potato and wheat starch.

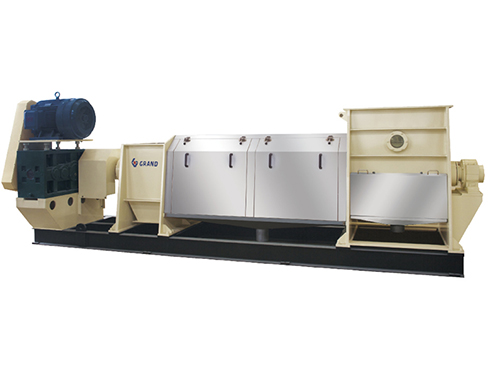

Get more Spiral squeezed machine

Spiral squeezed machine

The spiral squeezed machine is suitable for dehydration of wet materials such as starch, feed and other industries. Its structure is a conical shell with a built-in conical spiral belt of unequal pitch, which forms a double factor of pitch length and height during rotation. The dehydrated material is discharged from the discharge end, and the extruded water flows out through the screen holes in the shell. The compression ratio is large, the dehydration effect is good, the discharge moisture is low, the operation is stable without vibration, and The production can be performed continuously.

Get more Closed filter

Closed filter

Closed filter is a high-efficiency, energy-saving, closed operation precision clarification filtration equipment, which is widely used in chemical, oil, petroleum, paint, food, pharmaceutical and other industries. The product has a unique design structure, small volume, high filtration efficiency, high transparency of the filtrate, good fineness, no material loss, no consumption of filter paper, filter cloth or filter core, etc. Therefore, the filtration cost is very low, and the equipment is easy to operate, maintain and clean. Mainly it is used in food, medicine, beverages, grease, petrochemical products, organic chemicals, paints and varnishes, resins, inorganic chemicals, minerals, etc.

Get more Germ cyclone

Germ cyclone

The germ cyclone is mainly used for the germ separation of crops, including corn, wheat, beans and so on. In the production process of corn starch, after coarse crushing, the germ is separated by swirling under a certain pressure to achieve the purpose of extracting germ, which is an ideal equipment to improve the yield of starch and germ. The equipment is simple in structure, advanced in design, pays attention to materials, durable, stable in operation, and has good working performance. The equipment is mainly composed of a bracket, a swirl tube, a feed pipe, and a discharge pipe.

Get more Suspension centrifuge

Suspension centrifuge

XJZ type centrifuge is a fully automatic unloading centrifuge with mechanical discharge. All parts in contact with materials and water and steam pipelines are made of stainless steel or corrosion-resistant materials to ensure the cleanliness of the products after separation. Pneumatic mechanical scraper discharge makes the discharge safe and reliable, it is suitable for separating suspensions containing medium and fine-grain crystals.

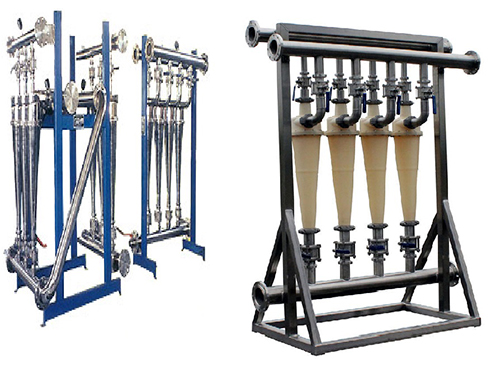

Get more Twelve-stage cyclone separator

Twelve-stage cyclone separator

The twelve-stage cyclone separator is used to purify and wash starch milk. Its main purpose is to remove soluble and insoluble protein and fine fiber sugar to purify starch. Compared with the disc separator, it has the advantages of simple equipment structure, reliable operation and convenient maintenance. It can be used under certain differential pressure. Separation of 4μ size particles, which uses centrifugal force to separate suspended particles with different particle sizes and specific gravities. The centrifugal force of the particles, the particles of specific gravity in the slurry move to the wall of the cyclone barrel and spin down. Finally, underflow with a larger concentration, particles with a smaller specific gravity rotate upwards around the center and overflow with a lower concentration.

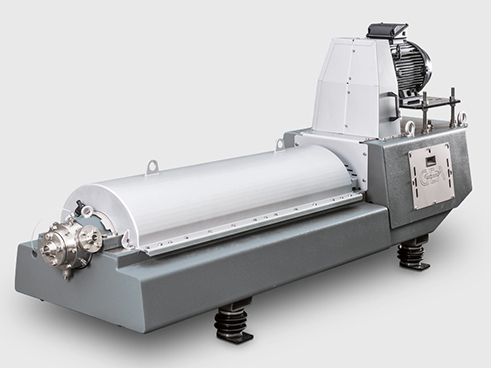

Get more Decanter

Decanter

The three-phase separating decanter centrifuge can realize the separation of two different density liquids. At the same time, the solids will also be separated and discharged.The material enters the decanter centrifuge through the feed pipe and enters the centrifugal zone through the distributor. the screw conveyor transports solids to the solids discharge port. the liquid level can be adjusted by installing adjustment rings with different inner diameters. The separation of the two liquids takes place in the separation zone, where the lighter phase flows towards the center of the drum and the heavier phase flows towards the drum wall. For the discharge of liquids, the three-phase separating decanter centrifuge offers various designs. Liquid can be discharged by gravity or by centripetal pump.The specific design depends on the product to be separated and the customer's installation plan.

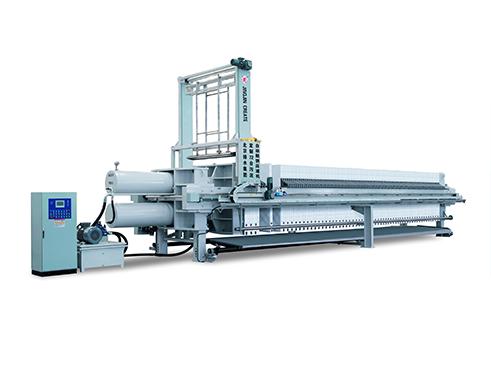

Get more Filter press

Filter press

Filter press is the gluten dewatering machine used in corn starch process. It is equipped with PLC, relay control and many other safety-guarding devices, therefore the operation will be automatic and easy to control, and the operator will work safely. Girder is equipped with abrasion-proof nonmetallic tracks, which are formed in one piece. It adopts bridge-type flexible frame and is the suitable for solid and liquid separation.

Get more Vacuum drum filter

Vacuum drum filter

The vacuum drum filter has a folding belt type and a scraper type, which is a filtering device for continuous suction filtration, desiccation and automatic discharge under the action of vacuum.During the working process, the material in the tank is under vacuum suction, the liquid penetrates through the filter cloth, enters the distribution valve through the suction pipe, and then exits the liquid pipe of the distribution valve After entering the vapor-liquid separator, the solid matter is left on the filter cloth to form a filter cake. The filter cake is automatically discharged by the discharge roller under the driving of the filter cloth. The filter cloth enters the cloth washing box through the automatic deviation-correcting device, and is regenerated by double-sided washing with high-pressure washing water, and then returns to the surface of the drum after the tension roller and starts a new filtering work .During filtration, under the vacuum suction, the separated filtrate passes through the filter cloth, the filter chamber and the filter tube to the distribution valve, and is discharged through the automatic discharge cylinder, while the solid particles are retained A filter cake is formed on the surface of the filter cloth. After the filter cake turns out of the liquid surface, it successively enters the dehydration zone and the discharge zone. The filter cake in the discharge area is blown up by the compressed air and removed by the scraper. At this point, a filtration cycle is completed. Then transfer to the filter slurry and start the next working cycle.

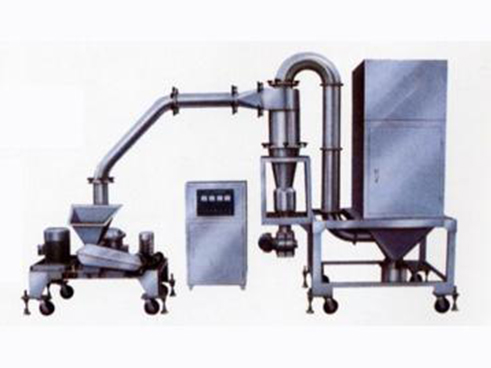

Get more Pulverizer

Pulverizer

The machine is composed of three parts: main machine, auxiliary machine and electric control box. It has various properties such as winnowing type, no screen, no net, uniform particle size, etc. The production process is continuous.

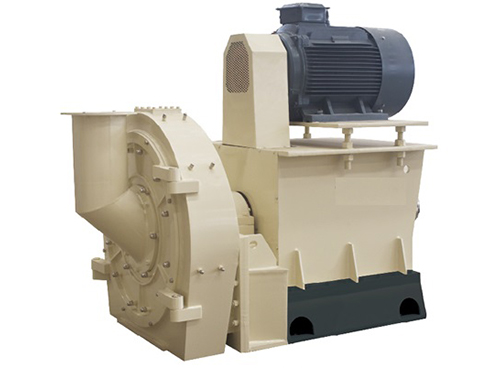

Get more Grind mill

Grind mill

DTM series corn grind mill is a coarse crushing equipment for wet corn starch production. The soaked corn is coarsely crushed by grades, so that the endosperm is broken and completely separated from the seed coat and embryo, which provides conditions for subsequent refining and starch refining. Due to the adjustable disk spacing, it can also be used for soybean crushing after soaking in a soy product factory. The machine is simple in structure, reliable in sealing, stable in performance, large in output, which has the smallest maintenance amount ,the lowest energy consumption, easy operation and maintenance, and certain self-protection functions compared with the same type of equipment.

Get more Pin mill

Pin mill

Pin mill is a high-efficiency modern fine grinding equipment. In addition to the advantages of compact structure, short process route, easy operation, large production capacity, small footprint, etc. It has the following characteristics: good product quality, high yield, simplifying the starch production process and improving the lubrication of bearings.

Get more Vibrating fluidized bed

Vibrating fluidized bed

The Structure principle of vibrating fluidized bed dryer is that the vibration motor makes the machine vibrate. The material jumps forward under the action of the excitation force in this given direction. At the same time, it inputs the hot air from the bottom of the bed and makes the material in a fluidized state , therefore Full contact with hot air to achieve the ideal drying effect.

Get more Spray dryer

Spray dryer

The spray drying technology is that the air is filtered and heated, and enters the air distribution box at the top of the dryer, and the hot air enters the drying chamber in a spiral shape. The liquid material is high-speed centrifugal atomized to tiny droplets on the top of the dryer, it can be dried into finished product in a very short time in parallel flow contact with hot air. The finished product is continuously output from the bottom of the dryer and it is transported to the cyclone separator, and the exhaust gas is evacuated by the induced draft fan. It is used widely in starch sugar, sugar alcohol, milk powder, amino acid, pectin, resin, chemical industry, food industry etc.

Get more MQG series airflow dryer

MQG series airflow dryer

The MQG series airflow dryer uses high-speed hot airflow to suspend the material to be dried, and the pulse airflow generated by the change of the pipe diameter makes the material continuously roll over, and the material is dried during the airflow transportation process. It is used for the final drying of powdery and flake materials such as corn and potato starch, protein powder and some heat-sensitive materials.

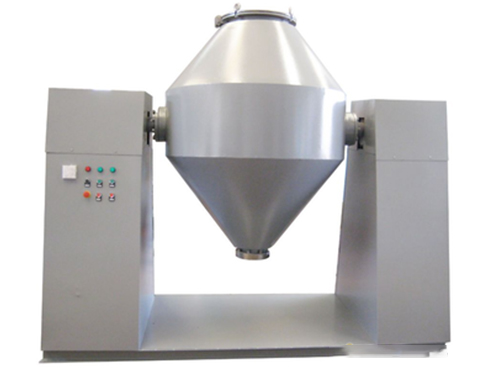

Get more Double cone rotary vacuum dryer

Double cone rotary vacuum dryer

The double cone rotary vacuum dryer is a new type of dryer that integrates mixing and drying. Matching the condenser, vacuum pump and dryer to form a vacuum drying device. Advanced design, simple internal structure,be easy to clean, all materials can be discharged, easy to operate, it can reduce labor intensity and improve working environment. At the same time, as the container itself rotates, the material also rotates but no material is accumulated on the wall, so the heat transfer coefficient is high and the drying rate is large, which not only saves energy, but also the material is dried uniformly and fully, and the quality is good. It is used widely in the drying of materials in pharmaceutical, chemical, food, dye and other industries.

Get more Tube bundle dryer

Tube bundle dryer

GZG tube bundle dryer is a contact dryer, its structure is fixed so that the shell can be driven with a shovel to heat the tube bundle. The steam enters the tube through the rotary joint, transfers heat and becomes condensed water, and the moisture in the material is heated outside the tube to become steam and is discharged by the dehumidifying fan. And the material shovel push the material from the inlet to the outlet to be dried. It can be used widely in the drying of loose wet materials in chemical industry, light industry, food and feed industries.

Get more

Citric acid

Citric acid

Citric acid monohydrate occurs as colorless crystals or as white, crystalline powder with a strongly acidic taste. It is efflorescent in dry air, very soluble in water, freely soluble in ethanol (96%) and sparingly soluble in ether.

Get more

Over the years, our company has completed different scales of starch, starch glucose and other starch biotransformation production line construction in Middle East, South America, Southeast Asia, Africa and China by EPC and EPCM.

Get moreWuhan Friendship New Tech Co.,Ltd is a well-known engineering company specializing in corn wet milling industry both domestic and overseas,and providing engineering consulation, engineering design, complete production line, installation and commissioning, personnel training and other services.

- Wuhan Friendship New Tech Co., Ltd. Tel:86-27-59730998

- Add:4F,Bldg. 5, No.35 Optical Valley Road,East Lake High-tech Development Zone,Wuhan City, China

Copyright © 2019 Wuhan Friendship New Tech Co., Ltd. All rights Reserved

Record No.: Hubei ICP No.: 18017616-1