Website on alibaba: whfn.en.alibaba.com

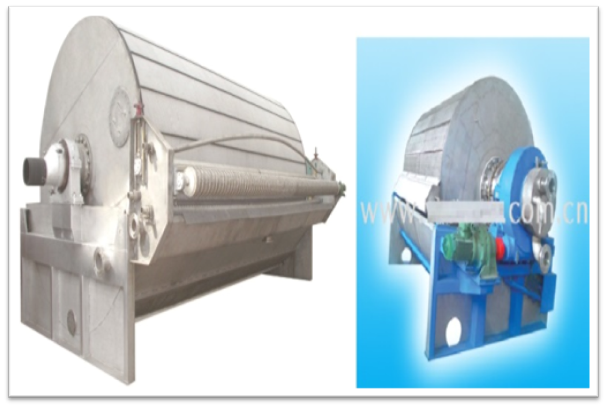

Vacuum drum filter

The vacuum drum filter has a folding belt type and a scraper type, which is a filtering device for continuous suction filtration, desiccation and automatic discharge under the action of vacuum.During the working process, the material in the tank is under vacuum suction, the liquid penetrates through the filter cloth, enters the distribution valve through the suction pipe, and then exits the liquid pipe of the distribution valve After entering the vapor-liquid separator, the solid matter is left on the filter cloth to form a filter cake. The filter cake is automatically discharged by the discharge roller under the driving of the filter cloth. The filter cloth enters the cloth washing box through the automatic deviation-correcting device, and is regenerated by double-sided washing with high-pressure washing water, and then returns to the surface of the drum after the tension roller and starts a new filtering work .During filtration, under the vacuum suction, the separated filtrate passes through the filter cloth, the filter chamber and the filter tube to the distribution valve, and is discharged through the automatic discharge cylinder, while the solid particles are retained A filter cake is formed on the surface of the filter cloth. After the filter cake turns out of the liquid surface, it successively enters the dehydration zone and the discharge zone. The filter cake in the discharge area is blown up by the compressed air and removed by the scraper. At this point, a filtration cycle is completed. Then transfer to the filter slurry and start the next working cycle.

1、It is mainly used in the filtration and dehydration of fermentation liquids of raw materials such as penicillin in the pharmaceutical industry, the filtration and dehydration of metal hydroxide slurry, coal preparation wastewater, copper ore, the filtration and dehydration of corn protein, the filtration and dehydration of wheat A starch, and the citric acid fermentation broth. Deslagging, etc.

2、It is mainly used in the dehydration and filtration of materials with fine particle size and low viscosity in petrochemical, mining, chemical and other industries.

(1) Personalized design to meet the needs of different customers

(2) Large production capacity, low moisture content of filter cake, easy to unload

(3) Simplified process layout and good economic benefits

(4) The filtrate has high clarity and high material recovery rate

(5) Excellent production environment, simple and convenient operation