Website on alibaba: whfn.en.alibaba.com

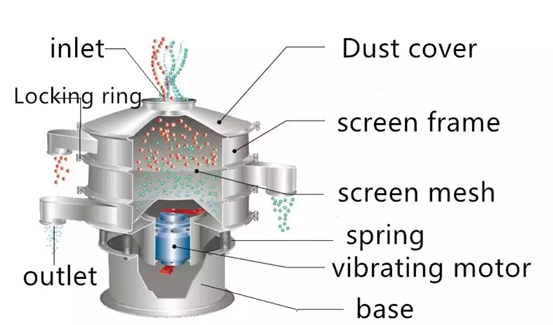

Vibrating screen

The vibrating screen is a high-precision fine powder screening machine with low noise and high efficiency. It takes 3-5 minutes to change the net quickly. It is fully enclosed and suitable for screening and filtering of particles, powder and mucilage. The vibrating screen is made up of an upright motor as an excitation source. The upper and lower ends of the motor are equipped with an eccentric weight to convert the rotary motion of the motor into a horizontal, vertical, and inclined three-dimensional motion, and then transmit this motion to the screen surface. . Adjusting the phase angles of the upper and lower ends can change the trajectory of the material on the screen surface.

1. Industry: resin powder, pigment, washing powder, micro powder, paint, soda ash, lemon powder, rubber, plastic, etc.

2. Abrasives and ceramics industry: alumina, quartz sand, mud, spray soil.

3. Food industry: sugar, salt, alkali, monosodium glutamate, milk powder, soy milk, yeast, juice, soy sauce, vinegar, etc.

4. Paper industry: coating paint, clay mud, black and white liquid, waste liquid, papermaking liquid, waste water recycling.

5. Metallurgical industry: titanium oxide, zinc oxide, electromagnetic materials, metal powder, electrode powder, etc.

6. Pharmaceutical industry: Chinese medicine powder, Chinese medicine liquid, western medicine powder, western medicine liquid, Chinese and Western medicine granules, etc.

7. Environmental protection: garbage, human and animal waste, waste oil, food wastewater, wastewater treatment, etc.

The three-dimensional vibrating screen is made up of an upright motor as an excitation source. The upper and lower ends of the motor are equipped with an eccentric weight to convert the rotary motion of the motor into a horizontal, vertical, and inclined three- The motion of the sieve to make the material expand and involute on the screen surface, so the series of vibrating screens is called a vibrating screen. The vibrating screen has the advantages of long track of material running and high utilization Of screen surface. Adjusting the phase angle of the upper and lower ends of the hammer can change the movement track of the material on the screen surface. The material can be finely sieved and probability sieved.

Technical Parameters | |||||

Model | XZS-400 | XZS-600 | XZS-800 | XZS-1000 | XZS-1800 |

Layers | 1-5 layers | 1-5 layers | 1-5 layers | 1-5 layers | 1-5 layers |

Powder(kw) | 0.37 | 0.55 | 0.75 | 1.1 | 3 |

Diameter(mm) | 400 | 600 | 800 | 1000 | 1800 |

Size(mm) | 600*500*600 | 800*700*700 | 1000*900*800 | 1200*1100*900 | 2100*1900*1300 |

Weight() | 60 | 100 | 150 | 200 | 1500 |