Website on alibaba: whfn.en.alibaba.com

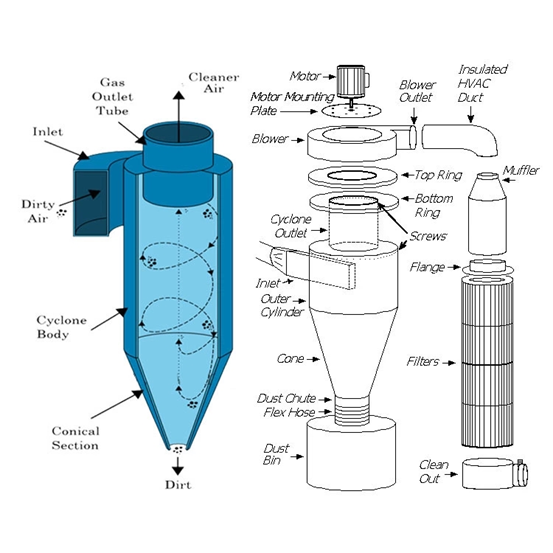

Cyclone

Cyclone Collector are often employed as an Initial Stage Collector to lighten heavy dusts loads before being sent to a Primary Stage Fabric Collector. By removing coarse particles from the gas stream, and allowing later stage Fabric Collectors to solely remove finer particles, these collectors increase the efficiency and service life of Fabric Collectors (Baghouses) and their Filters. Thus protecting your larger and most costly investment from unnecessary wear and tear.

It often named after the cyclone weather phenomenon, are large funnel shaped sheet metal tubes connected to ducts often used in woodshops, machine shops, manufacturing plants, and powder processing plants. Dust and debris are sucked in at the top. Air containing fine dust blows out of the other side of the top, while chips and large dust particles fall out of the bottom into a drum or bin. Dusty exhaust air is either blown outside or filtered again using media filtration.

1、Coarse particle size distribution

2、Higher products specific gravity

3、Lower gas density

4、Smaller outlet diameter. An increase in pressure drop also results.

Cyclone dust collector type | |||

Model | Air Volume | Size(mm) | Weight(kg) |

YTCY-01 | 750-1060m³/h | 460*390*1380 | 45 |

YTCY-02 | 1460-2060m³/h | 556*545*1880 | 85 |

YTCY-03 | 2280-3230m³/h | 711*700*2701 | 130 |

YTCY-04 | 4020-5700m³/h | 911*910*3040 | 220 |

YTCY-05 | 5500-7790m³/h | 1071*1605*3540 | 300 |