Website on alibaba: whfn.en.alibaba.com

Corn Starch

Corn starch is made by impregnating corn with 0.3% sulfurous acid, crushing, sieving, separating, dehydrating and drying. Mainly used in starch sugar, food, fermented products, etc.

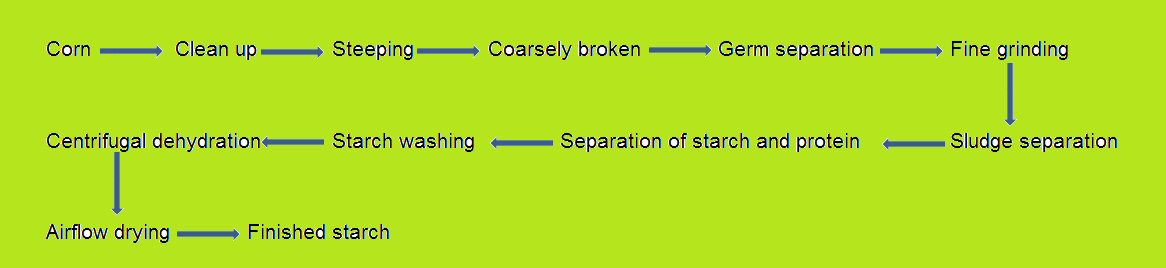

一、Process Flow

二、Process Description

1. Clean up

Screening and winnowing are used to clean up corn containing various dust mustard, organic and inorganic impurities.

2. Soaking

Corn soaking method generally adopts several or dozens of metal tanks connected by pipes, and the water pump is used to circulate the soaking water between the tanks and countercurrent soaking.

3. Coarse corn

The purpose of coarse crushing is to break the soaked corn into more than 10 small pieces in order to separate the germ.

Most of the coarse corn crushing adopts disc crusher. Coarse crushing can be carried out twice. Crush the corn to 4-6 pieces for the first time to carry out the germ separation; break the corn to more than 10 pieces for the second time to make the embryos fall off and carry out the second germ separation.

4. Germ separation

Use a germ cyclone to separate.

5. Corn grind

In order to extract the starch, the mixture of corn pieces and part of the starch after the separation of the germ must be ground to destroy the corn cell cells, free starch granules, and separate the fiber and the bran.

6. Fiber screening

After the corn is crushed, it is necessary to separate the fiber and starch slurry, extract the corn fiber with a pressure curved sieve, and then dehydrate and dry to obtain the by-product of corn starch processing-fiber feed

7. Starch separation and refining

The starch slurry contains a large amount of protein, which needs to be separated from the starch milk. Most of them are separated by a starch centrifuge to remove the protein, and then use a 12-stage cyclone to wash the starch to further remove the protein and soluble matter.