Website on alibaba: whfn.en.alibaba.com

Cassava Starch

Cassava starch is to separate the starch in the raw material of cassava from cellulose, white, inorganic and other substances. In the production process, the root starch is insoluble in cold water and has a specific gravity greater than that of water. With water and special mechanical equipment, the starch is separated from the suspension of water to achieve the purpose of recovering starch. Cassava starch is mainly used as raw material in food, sugar, medicine, feed, textile, paper, chemical industry and other industrial sectors.

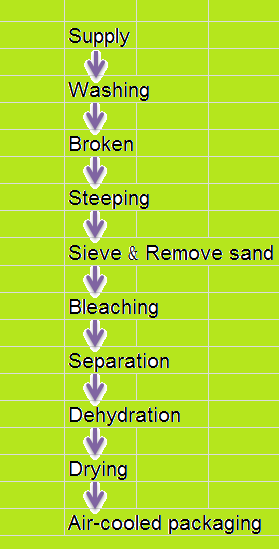

一、Process Flow

二、Process Description

1. The potato collecting machine and conveyor are used to transport the cassava from the storage yard to the washing machine.

2. The cassava raw material rotates and rolls forward with the rotation of the cylinder wall, spraying, rinsing, bathing, grinding, cleaning, and peeling with water as the medium (water distribution is 1: 4).

3. The cassava raw material of the disintegrating machine is rotated and rolled forward along with the wall of the garden barrel, sprayed, rinsed, bathed, bruised, cleaned and peeled with water as the medium (water distribution is 1: 4).

4. Sift the dilute starch milk with pressure curved sieve and centrifugal sieve to separate the starch milk from the fiber.

5. Adjust the pH value of the milk slurry to control the microbial activity and fermentation and saccharification; accelerate the separation of starch and other impurities; bleach the gelatin of the outer layer of the starch granules to make the starch granules last white.

6. A disc separator is used to wash, refine and concentrate starch emulsion.

7. Adopt scraper centrifuge for slurry dewatering.

8. Adopt scraper centrifuge for slurry dewatering.

9. After air cooling, weigh and pack into the warehouse for storage.