Website on alibaba: whfn.en.alibaba.com

Glucose Monohydrate

Glucose monohydrate is a monosaccharide organic compound produced by starch hydrolysis and acid hydrolysis or enzymatic hydrolysis, which is widely used in food, medicine, daily chemical and other industries.

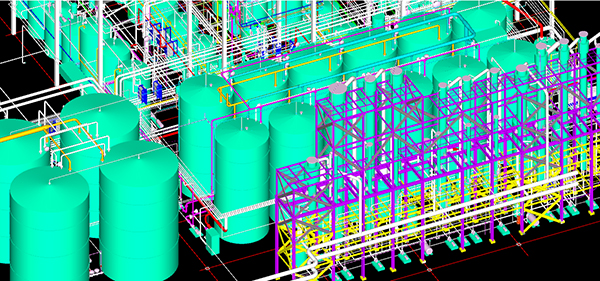

一、Process Flow

二、Process Description

(1) Adjustment of starch milk: adjust the concentration of starch in the starch factory to 17-19Be with water, and adjust the pH value and temperature.

(2) Liquefaction: Transfer the starch milk to the buffer tank, add the appropriate amount of enzyme preparation, and use the ejector to heat and mix to keep warm and liquefy.

(3) Saccharification: The liquefied liquid is cooled to a certain temperature, the pH value is adjusted, an appropriate amount of enzyme preparation is added, and transported to the saccharification tank, the saccharification reaches the required DE value within a specified time, and the material is discharged.

(4) Filtration and decolorization: The glucose syrup passes through the filter to remove protein and other impurities, then add activated carbon at the appropriate temperature to decolorize within a specified time, and then send it to the filter to remove the activated carbon, and the clear liquid is sent to the next process.

(5) Ion exchange: At a certain temperature, the glucose solution enters the cation resin and anion resin exchangers to remove inorganic salts and pigments and other organic impurities to obtain refined filtrate.

(6) Evaporation: The glucose solution is sent to the evaporator through a precision filter to be concentrated to achieve the concentration of the desired product, and then transferred to the next process.

(7) Cooling and crystallization: Add a certain amount of seed crystals to the concentrated glucose syrup, gradually cool and cool down, and crystallize glucose.

(8) Centrifugal separation: The sugar paste is sent to the centrifuge to separate the wet sugar, and the mother liquor is returned to the sleeve for use.

(9) Drying: Wet sugar is sent to the dryer for drying to obtain the product with required moisture.

(10) Finished product: glucose products are weighed and packaged, and stored in the warehouse.