Website on alibaba: whfn.en.alibaba.com

Anhydrous Glucose

Anhydrous glucose is a monosaccharide organic substance formed by starch hydrolysis, acid hydrolysis or enzymatic hydrolysis, that is, glucose without crystal water, which is colorless crystal or white crystalline powder; odorless and sweet, It is widely used Food, medicine, daily chemical and other industries.

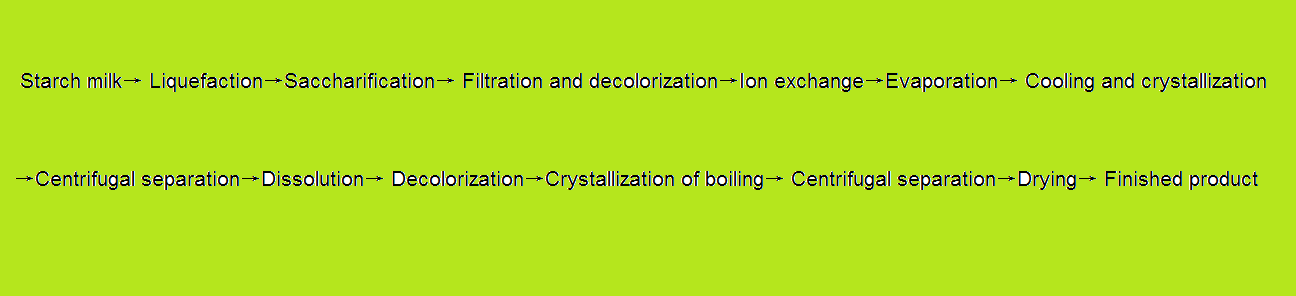

一、Process Flow

二、Process Description

(1) Adjustment of starch milk: adjust the concentration of starch in the starch factory to 17-19Be with water, and adjust the pH value and temperature.

(2) Liquefaction: Transfer the starch milk to the buffer tank, add the appropriate amount of enzyme preparation, and use the ejector to heat and mix to keep warm and liquefy.

(3) Saccharification: The liquefied liquid is cooled to a certain temperature, the pH value is adjusted, an appropriate amount of enzyme preparation is added, and transported to the saccharification tank, the saccharification reaches the required DE value within a specified time, and the material is discharged.

(4) Filtration and decolorization: The glucose syrup passes through the filter to remove protein and other impurities, then add activated carbon at the appropriate temperature to decolorize within a specified time, and then send it to the filter to remove the activated carbon, and the clear liquid is sent to the next process.

(5) Ion exchange: At a certain temperature, the glucose solution enters the cation resin and anion resin exchangers to remove inorganic salts and pigments and other organic impurities to obtain refined filtrate.

(6) Evaporation: The glucose solution is sent to the evaporator through a precision filter to be concentrated to achieve the concentration of the desired product, and then transferred to the next process.

(7) Cooling and crystallization: Add a certain amount of seed crystals to the concentrated glucose syrup, gradually cool and cool down, and crystallize glucose.

(8) Centrifugal separation: The sugar paste is sent to the centrifuge to separate the wet sugar, and the mother liquor is returned to the sleeve for use.

(9) Dissolution: Wet sugar is heated to a certain temperature and kept dissolved at this temperature.

(10) Decolorization: add a certain amount of activated carbon to the syrup, maintain a certain temperature, remove the pigment, and filter the resulting clear liquid.

(11) Crystallization of boiled sugar: Concentrate gradually in a vacuum boiler, add a certain amount of anhydrous glucose seed crystals, and crystallize.

(12) Centrifugal separation: the sugar paste is sent to the centrifuge to separate the wet sugar, and the mother liquor is returned to the sleeve for use.

(13) Drying: The wet sugar is sent to the dryer for drying to obtain the product with required moisture.

(14) Finished product: Glucose products are weighed and packaged and stored in the warehouse.