Website on alibaba: whfn.en.alibaba.com

Citric Acid

Citric acid is colorless translucent crystals or white granules or white crystalline powder, odorless, extremely acidic, astringent, slightly corrosive, strong deliquescent, and accompanied by the formation of crystalline water compounds in humid air Slightly deliquescent. At present, it is mostly produced by microbial fermentation and is widely used in food, daily chemical, textile, pharmaceutical, environmental protection and other industries.

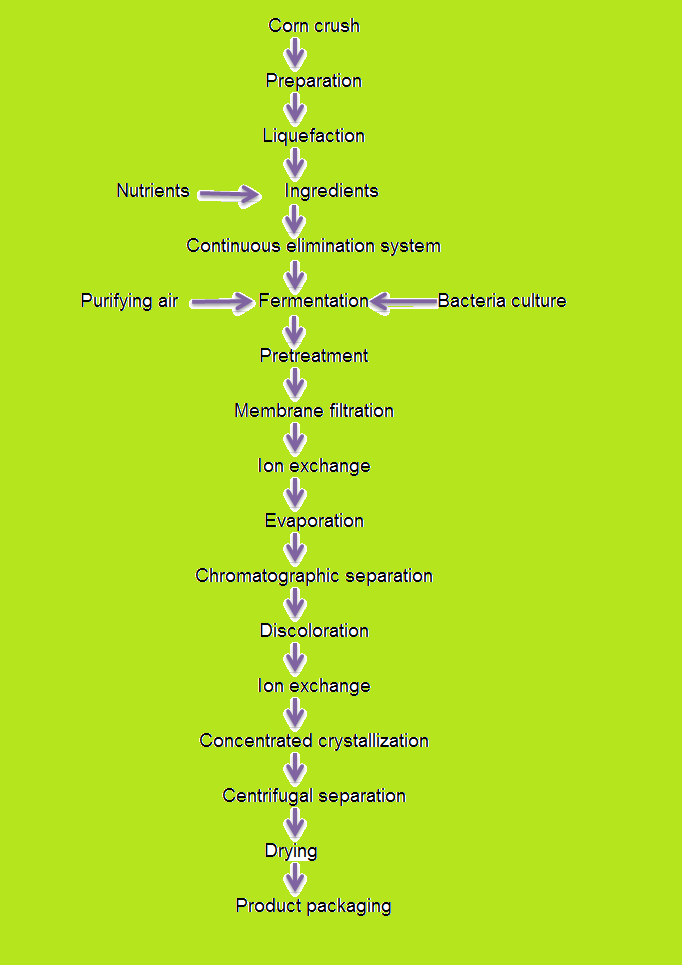

一、Process Flow

二、Process Description

(1) Crush the corn to the required particle size, then adjust the pH of the corn flour with water, adjust the pH value, add the enzyme preparation, stir evenly, spray liquefaction, the liquefied liquid is sent to the filter to remove the protein residue, and the clear liquid is sent to the next Process.

(2) The sugar solution and nutrient nitrogen source are sent to the fermentation process through a continuous sterilization system, and the sterile wind is passed to adjust the pH value, and the temperature is reduced to 37 ° C. A certain amount of bacteria, ventilation, and fixed stirring speed are connected, after 65 After hourly fermentation, the reducing sugar is consumed and the fermentation is over.

(3) The fermentation broth is removed by a filter machine to remove acid residue, and then further purified by membrane filtration, cooled to a certain temperature, entered into a cation resin and anion resin exchange column to remove impurities such as inorganic salts and pigments, and then concentrated to 60% by an evaporator The concentration is sent to the chromatographic separation process.

(4) The citric acid mixture is chromatographically separated to extract high-purity citric acid, decolorized by a carbon column, and then processed by a cation resin and anion resin exchange column to obtain refined citric acid, which is sent to the next process.

(5) The citric acid is sent to the evaporator for vacuum concentration, and then enters the evaporative crystallizer to obtain the crystal slurry, and then enters the centrifuge for solid-liquid separation to obtain citric acid crystals, which is sent to the dryer for drying to obtain the required requirements. Moisture products.

(6) The citric acid product is measured and packaged and stored in the warehouse.