Website on alibaba: whfn.en.alibaba.com

Gellan Gum

Gellan gum is an extracellular polysaccharide gum produced by aerobic fermentation in a medium woven with glucose as the carbon source, ammonium nitrate as the nitrogen source, and some inorganic salts. Agent, widely used in food, beverage, daily chemical and other industries.

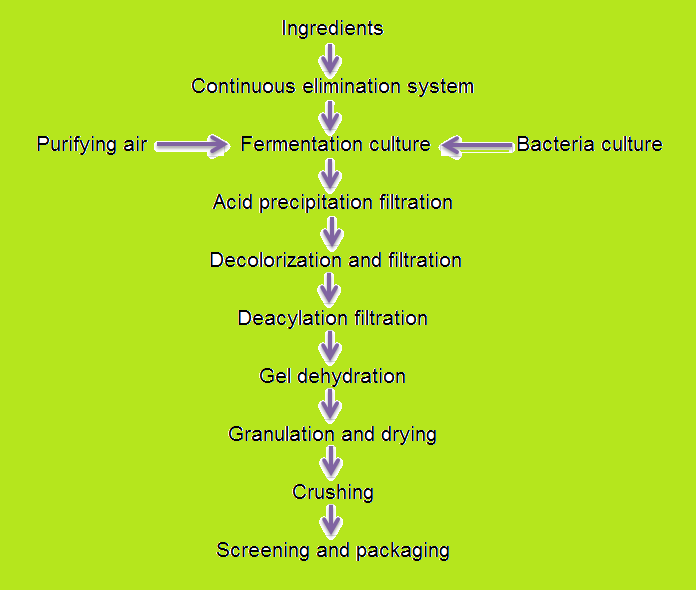

一、Process Flow

二、Process Description

(1) Ingredients: Add a certain amount of desalted water according to the ingredients table to prepare the medium.

(2) Continuous elimination system: The culture medium is sterilized by a continuous disinfection system and sent to the fermentation tank.

(3) Fermentation culture: Sterile medium in the fermenter is fed with sterile air, pH value is adjusted, and the cultivated strains are connected to aerobic fermentation culture at a certain temperature, speed, and ventilation to produce extracellular polysaccharides Colloid.

(4) Acid precipitation filtration: The fermentation broth is sent to the acid precipitation tank, added with a certain concentration of hydrochloric acid, adjusted to the required pH value range, there will be fibrous precipitate under uniform stirring, and then the filter cake is separated and collected by the filter machine and sent to the next Process.

(5) Decolorization and filtration: crush the filter cake and send it to the decolorization tank, add a certain amount of alcohol, stir evenly, decolorize, and then send it to the separator for solid-liquid separation, and the filter cake is sent to the next process.

(6) Deacylation filtration: crush the filter cake and send it to the deacylation tank, add a certain amount of water, heat to a certain temperature, adjust the pH value to deacylation, after the deacylation is completed, add acid to adjust to the required pH value, and then The temperature is raised, and the solution is sent to a filter and filtered to obtain a clear solution.

(7) Gel dehydration: The clear liquid is sent to the gel tank, a certain amount of sodium chloride is added to dissolve and cool the gel, the water is separated out, then the filter is separated, and most of the water is removed to obtain a colloid.

(8) Granulation and drying: The colloid is granulated by a bar-making machine and sent to a vacuum dryer for drying to obtain the product with the required moisture.

(9) Crushing: Send the dried product to the crusher for crushing.

(10) Screening and packaging: The crushed powder is passed through a vibrating screen, measured and packaged into the warehouse.